Photovoltaic solar panels absorb sunlight as a source of energy to generate direct current electricity. A photovoltaic (PV) module is a packaged, connected assembly of photovoltaic solar cells available in different voltages and wattages.

Photovoltaic modules constitute the photovoltaic array of a photovoltaic system that generates and supplies solar electricity in commercial and residential applications. Difference Between Monocrystalline and Polycrystalline Solar Panels are given below with advantages and advantages of both types.

Mono-crystalline solar panels:

The mono-crystalline solar panels cells are also known as single crystalline cells. They are incredibly easy to identify because they are a dark black in colour.

Mono-crystalline cells are made from an incredibly pure form of silicon, which makes them the most efficient material for the conversion of sunlight into energy.

Additionally, mono-crystalline cells are also the most space-efficient form of silicon solar cell. They also have the advantage of being the ones that last the longest out of all the silicon-based solar cells.

In fact, many manufacturers will offer warranties of up to 25 years on this type of system – a warranty that lasts half of their expected life. However, while these systems are superior, they do come at quite a hefty price.

Mono-crystalline cells are the most expensive option out of all of the silicon solar cell types, mostly because the four-sided cutting system results in a large amount of waste. Poly-crystalline acts as a cheaper alternative.

➢ Advantages of Mono-crystalline solar Cell:

Monocrystalline solar panels have the highest efficiency rates since they are made out of the highest-grade silicon.The efficiency rates of mono-crystalline solar panels are typically 15-20%. Sun Power produces the highest efficiency solar panels on the U.S. market today. Their E20 series provide panel conversion efficiencies of up to 20.1%. Update (April, 2013): Sun Power has now released the X-series at a record-breaking efficiency of 21.5%.Monocrystalline silicon solar panels are space-efficient. Since these solar panels yield the highest power outputs, they also require the least amount of space compared to any other types.Mono-crystalline solar panel produce up to four times the amount of electricity as thin-film solar panels.Mono-crystalline solar panel live the longest. Most solar panel manufacturers put a 25-year warranty on their mono-crystalline solar panel.Tend to perform better than similarly rated poly-crystalline solar panel at low-light conditions.

➢ Disadvantages of Mono-crystalline solar Cell:

Mono-crystalline solar panels are the most expensive.From a financial standpoint, a solar panel that is made of poly-crystalline silicon (and in some cases thin-film) can be a better choice for some homeowners.If the solar panel is partially covered with shade, dirt or snow, the entire circuit can break down. Consider getting micro-inverters instead of central string inverters if you think coverage will be a problem. Micro-inverters will make sure that not the entire solar array is affected by shading issues with only one of the solar panels. The Czochralski process is used to produce mono-crystalline silicon. It results in large cylindrical ingots. Four sides are cut out of the ingots to make silicon wafers. A significant amount of the original silicon ends up as waste.Monocrystalline solar panels tend to be more efficient in warm weather.Performance suffers as temperature goes up, but less so than polycrystalline solar panel. For most home owners temperature is not a concern.

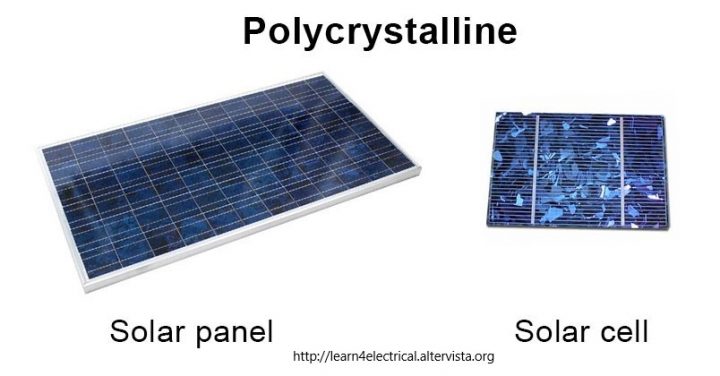

Poly-crystalline silicon Solar Panels:

The polycrystalline solar cells are also known as polysilicon and multi-silicon cells. They were the first solar cells to be developed when the industry started in the 1980s.

Most interestingly, polycrystalline cells do not undergo the same cutting process as the monocrystalline cells. Instead, the silicon is melted and then poured into a square mould. This is what creates the specific shape of the polycrystalline.

One of the benefits of this process is that the solar cells become much more affordable. This is because hardly any silicon is wasted during the manufacturing process.

However, they are less efficient than monocrystalline solar cells, and also require a lot more space. This is due to the fact that they have lower levels of purity than the single crystalline cell models.

Poly-crystalline also has a lower tolerance for heat than mono-crystalline. This means that they are unable to function as efficiently in high temperatures. This can be a massive disadvantage in areas with hot climates.

➢ Advantages of Poly-crystalline silicon Solar Panels:

The process used to make poly-crystalline silicon is simpler and cost less. The amount of waste silicon is less compared to mono-crystalline.Poly-crystalline solar panel tend to have slightly lower heat tolerance than mono-crystalline solar panel. This technically means that they perform slightly worse than mono-crystalline solar panels in high temperatures.Heat can affect the performance of solar panel and shorten their lifespans. However, this effect is minor, and most homeowners do not need to take it into account.

➢ Disadvantages of Poly-crystalline silicon Solar Panels:

The efficiency of poly-crystalline-based solar panel is typically 13-16%. Because of lower silicon purity, poly-crystalline solar panels are not quite as efficient as mono-crystalline solar panel.Lower space-efficiency. You generally need to cover a larger surface to output the same electrical power as you would with a solar panel made of mono-crystalline silicon. However, this does not mean every mono-crystalline solar panel perform better than those based on poly-crystalline silicon.Mono-crystalline and thin-film solar panels tend to be more aesthetically pleasing since they have a more uniform look compared to the speckled blue color of poly-crystalline silicon.