Residential>Troubleshooting & Repair ServicesGFCI OutletsAFCI BreakersWhole House Surge ProtectionElectrical Safety InspectionsSmoke & CO DetectorsGenerator InstallationElectrical Panel UpgradesDedicated CircuitsIndoor LightingLandscape LightingFan InstallationPool & Hot Tub WiringEV Charger InstallationWhole House RewiringHome Theater InstallationCommercial>Troubleshooting & Repair ServicesDedicated Computer CircuitsElectrical Safety InspectionsSurge ProtectionGenerator InstallationElectrical Panel UpgradesBucket Truck ServicesEquipment HookupsIndoor & Outdoor LightingReviewsService Areas>Montgomery County, PABucks County, PAChester County, PADelaware County, PABerks County, PAPhiladelphia County, PAPhotosTeamBlogDealsCommunityAchievementsComicsCareersCompanies

Beware Of Space Heaters: They Must Be On A Dedicated Line

It’s that time of year again. The cold air has finally entered the Southeastern, PA region, just in time for Christmas. Some of us are hoping for snow on the big day we gather to celebrate the birth of Christ. Others are envisioning a time when they are sprawled out on the beach again in the blazing sun with a romance novel. Either way, it’s winter-time in Pottstown, PA and many of us are dusting off the space heaters left in storage and plugging them in to keep warm.

KB Electric LLC received a call today from a customer that needed his burnt outlet replaced. Upon arrival, we found out why the customer’s receptacle was burnt: he had a space heater plugged into it. Space heaters MUST be on a dedicated line to ensure proper safety of the unit and the safety of your home. If you use a space heater or are thinking about buying a space heater for a room in your home, please take the time to read this blog as we go into more depth about space heaters on a dedicated line. Please also refer to one of our previous blogs here to learn more about space heater safety.

What Is a Dedicated Line?

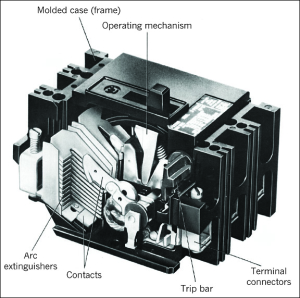

A dedicated line is a line that runs from your main electrical panel on its own circuit breaker to its own dedicated outlet/receptacle. This line/circuit is designated for only ONE appliance.

Why Do Space Heaters Needs To Be On A Dedicated Line?

The reason for a dedicated line is to not overload your electrical system because of its heavy electrical load that it produces. Dedicated lines prevent blown circuits and fuses, tripping breakers, electrical fires, overheating wires, and damage of appliances. Many appliances should have their own dedicated line and circuit breaker with dedicated outlet like refrigerators, microwaves, ranges, freezers, dryers, washing machines, space heaters, heaters, hot tubs, water pumps, sump pumps, A/C units, etc. (ANYTHING THAT DRAWS A LOT OF ELECTRICITY WHEN IN USE)

Your space heater is an “appliance” that needs to be on its own circuit breaker and line with its own outlet/receptacle because it draws a lot of electricity. If the space heater shares a circuit with multiple things in use, it can overheat the wires, cause an electrical fire, damage the space heater, and burn your outlets. IT IS A FIRE HAZARD TO HAVE A SPACE HEATER SHARING A CIRCUIT WITH OTHER APPLIANCES/DEVICES. PLEASE BE AWARE OF THIS WHEN YOU ARE PLUGGING IN YOUR SPACE HEATER.

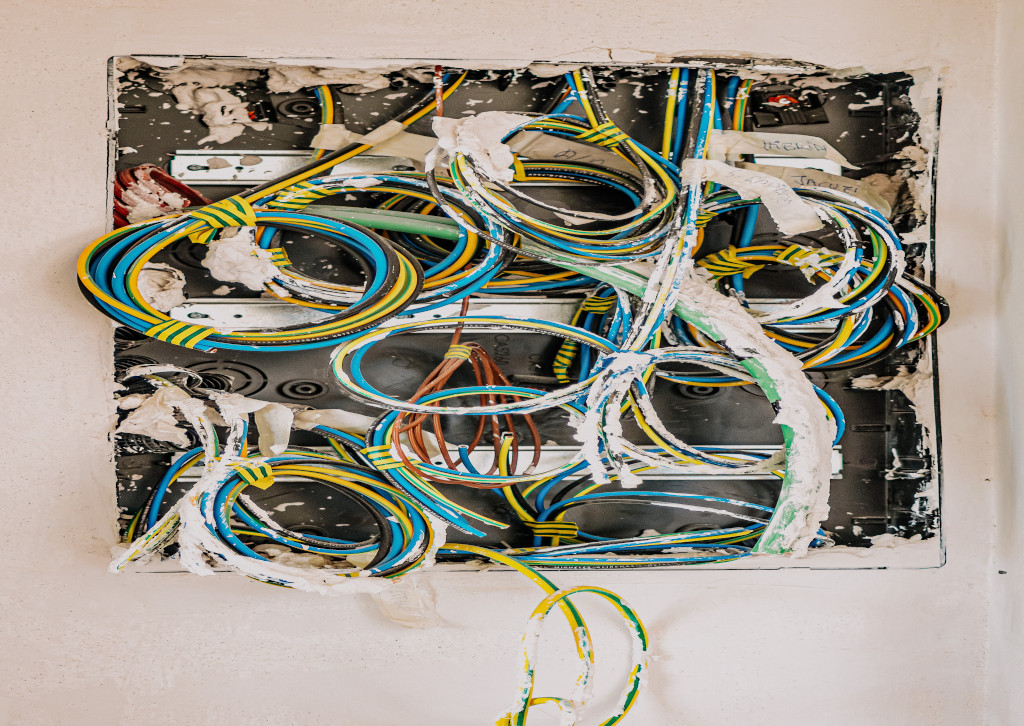

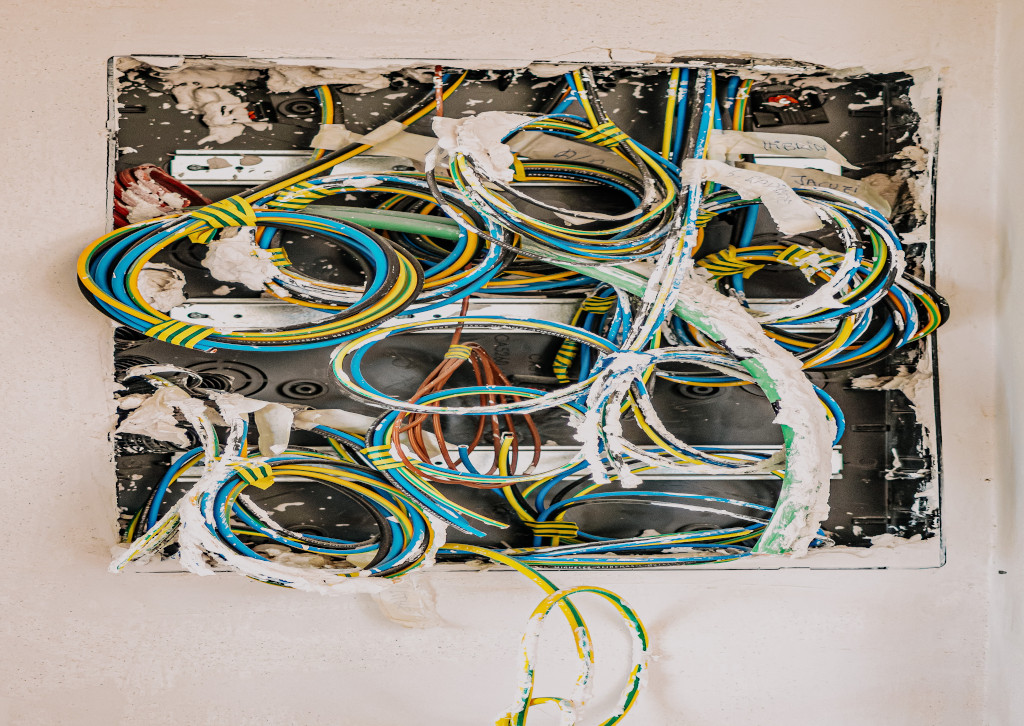

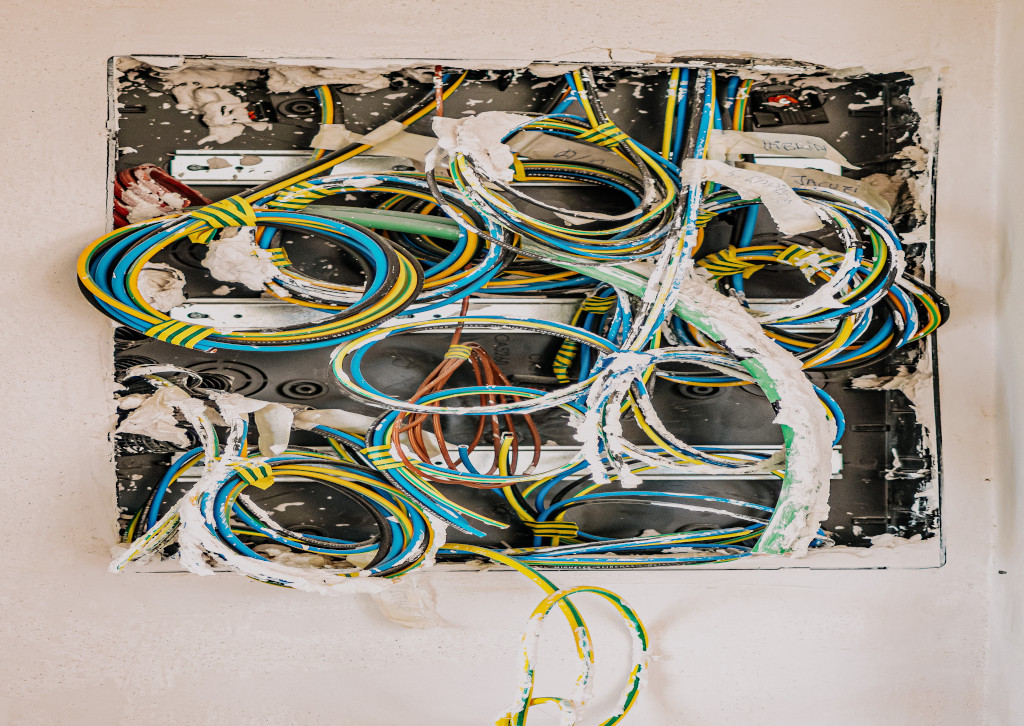

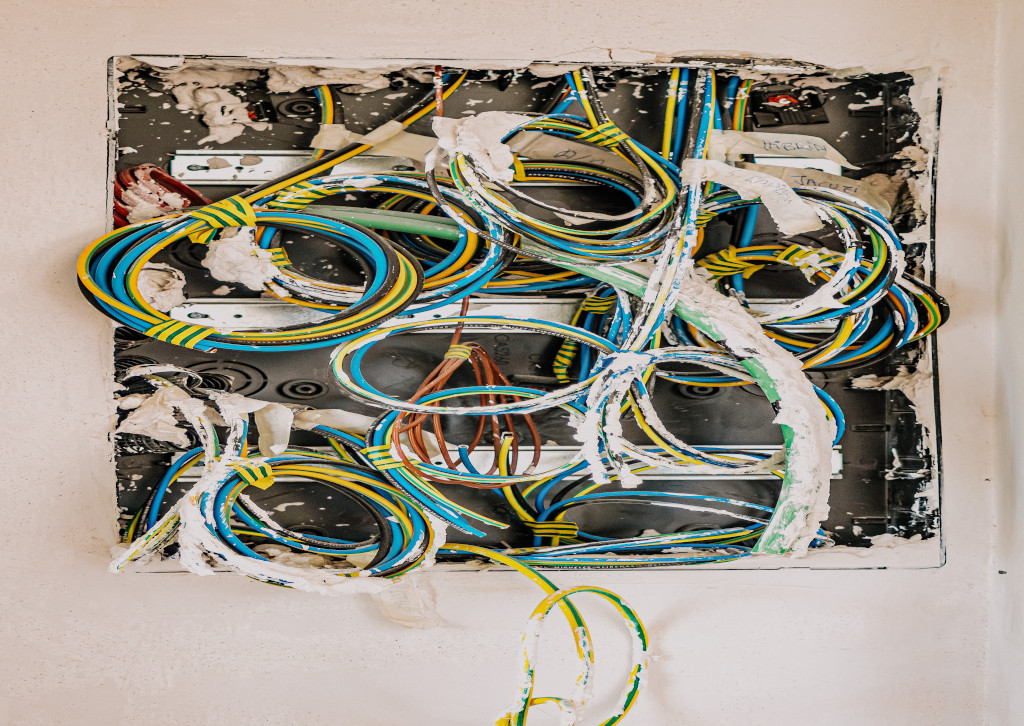

Burnt Outlet From Space Heater Not On A Dedicated Line

I Need a Dedicated Line For My Space Heater. Who Should I Call?

A licensed and insured electrician should be the only professional to install a dedicated line for your space heater. A dedicated line for any appliance consists of a dedicated outlet, circuit breaker in your main electrical panel, and a dedicated wire/line running from your main panel to the dedicated outlet. An electrician has the hands-on experience to install dedicated lines, as well as the NEC knowledge to install them correctly and safely.

Call KB Electric LLC today if you are in need of a dedicated line for your space heater. We are licensed and insured, family-owned and operated for over 15 years, and all of our technicians are background-checked, uniformed, and perform continuing education classes to be versed in the latest NEC requirements. (267) 467-3178

CATEGORIES

4-Prong OutletsAbout KB Electric LLCAttic FansBallast ReplacementBathroom LightingBollard LightsCable Outlet InstallationCarbon Monoxide DetectorsCeiling Fan InstallationChandelier InstallationChristmas Light SafetyCircuit BreakersCommercial Electrical Safety InspectionsCommercial ElectricianCommercial LightingCurrent Events with ElectricityCurrent Events: EnergyDeck LightingDeck Receptacles/OutletsDedicated CircuitsDeicing CablesDimmer SwitchesDisposing Light BulbsDoorbellsDryer Booster FansElectricity and Energy InnovationsElectric Baseboard Heater InstallationElectric Car Charging InstallationElectric Radiant Floor HeatingElectrical InformationElectrical InnovationsElectrical Panel UpgradeElectrical Remodeling ServicesElectrical Safety InspectionsElectrician vs. Electrical InspectorElectricity BillElectromagnetic FieldsEmergency DisconnectsEmergency Lighting and Exit Sign LightingEnergy Saving TipsEthernet Wall JacksEV Charging SafetyExhaust FansFestoon LightingGarage WiringGeneratorsGFCIsHigh Bay LightingHire a Licensed ElectricianHistory of Ceiling FansHistory of the Dimmer SwitchHistory of Electric CarsHome Electric Car Charging InstallationHot Tub WiringHouse RewireIn The NewsIntercom SystemsKitchen LightingKnob & Tube WiringLED Ballast BypassLED Christmas LightsLED Retrofit LightingLEDsLi-Fi TechnologyLight Color TemperatureLightingLightning FactsLow Voltage Landscape LightingMotion SensorsMoonlightingOutlet SafetyOutdoor Ceiling FansOutdoor Home Security Lighting TipsOutdoor Lamp PostsOutdoor LightingOutdoor Outlet CoversOutdoor Receptacles/OutletsOutdoor Shed WiringParking Lot LightingPendant LightingPhotocell SensorsPool WiringPower and Communication PolesPrivate Utility PolesProperty Management ElectricianRange HoodsRecessed LightsRecessed OutletsRenewable EnergyRomex WiringRV Home Electrical HookupSafety & PreventionShed WiringSingle Phase to Three PhaseSmall BusinessesSmart Light SwitchesSmart OutletsSmart ThermostatsSmoke DetectorsSolar Powered ElectricitySpace HeatersStorefront LightingSurge ProtectionSwimming Pool Electrical SafetySwimming Pool Area LightingSwimming Pool LightingThanksgiving FunTools of the TradeTrack Lighting InstallationTransformersTunable White LEDsTV Wall Mount InstallationTwist Lock ReceptaclesUnder Cabinet LightingUSB OutletsVideo Doorbells

The post Beware Of Space Heaters: They Must Be On A Dedicated Line appeared first on KB Electric LLC.