Electrician prepares, assembles, installs, and repairs electrical wiring, fixtures, and control devices. They work for electrical contractors or building maintenance departments or are self-employed.

Faulty wiring is a fire waiting to happen, and lousy workmanship can leave you with hefty bills for remedial work. To find an electrician you can trust, ask for recommendations and check out their online reviews.

An electrician handles the installation, repair and maintenance of electrical wiring and systems. They must have a thorough knowledge of electrical codes and safety procedures. An electrician must also have excellent communication skills to interact with customers, assistants and other crew members. An interest in subjects like math, science and physics is important for this career.

A high school diploma is the minimum educational requirement to become an electrician, although many vocational and technical schools offer career diplomas or associate degrees in electrical technology. These programs often include classroom instruction and lab work, followed by an apprenticeship where the student works under the supervision of a licensed journeyman electrician. Some programs also provide the opportunity to take state licensing exams at the end.

Most electricians start their careers as helpers, working under the guidance of a master electrician. As they gain experience, they may earn promotions to apprentice or journey worker. They can also choose to seek out their own apprenticeship opportunities through trade schools, independent electrical contractors or Associated Builders and Contractors. A journey person can also apply to become a master electrician after completing three years of experience and passing an exam.

Some electricians specialize in particular types of electrical systems. Residential wiremen install and maintain electrical wiring in homes, while inside wiremen do the same for commercial and industrial structures. Outside linemen spend their time outdoors, installing and maintaining cabling that runs from power plants to individual buildings. Telecommunications electricians lay wiring for phones and computers.

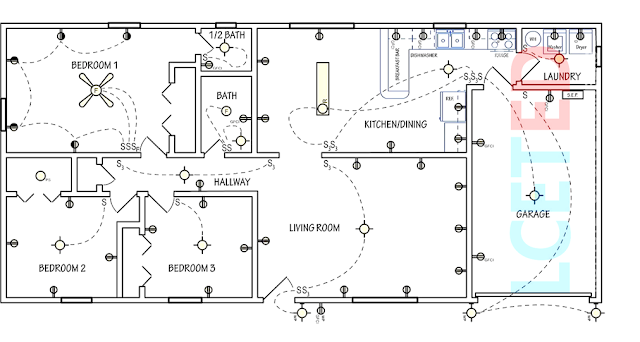

Electricians must have a strong understanding of blueprints, the technical diagrams that show where every wire is going. They also must be able to use hand tools, such as screwdrivers, pliers, knives and hacksaws, as well as power tools like drills and saws. In some states, including electricians must pass a written and practical exam to get their license. In addition to passing the test, electricians must have at least 7.5 years of experience in the installation, alteration and repair of wiring and appliances for electric light, heat and power in or on buildings and comparable facilities.

Licensing

Before any electrician can work professionally, he must get licensed. The licensing requirements vary by state, but they usually include apprenticeships, coursework and on-the-job training. The first step is an apprentice program, which generally combines classroom courses with hands-on instruction, typically under a journeyman electrician. This can take about four years to complete.

Once an apprentice has completed his training, he must pass an exam to become a journeyman electrician. The journeyman is then allowed to work on larger and more complex projects without supervision, and he is often the person who oversees other electricians on the job site. Some electricians choose to further their education by going to trade school or completing coursework that leads to a degree in electrical engineering or other relevant fields. These degrees can help them advance in their career and can help them earn higher salaries.

In some states, formal schooling helps to fast-track the journeyman’s license process. However, you must have seven and a half years of experience as a journey worker and pass an examination. Some electricians also pursue professional certifications to boost their resumes and make them more marketable to employers. These may include obtaining certificates in green energy, power testing or fire alarm systems.

Another important consideration for any electrician is insurance coverage. Liability insurance can protect them in the event of a lawsuit, which is a common risk of any business. In addition, it’s a good idea to have errors and omissions (E&O) insurance. This type of policy protects electricians against claims made by clients for damage caused to installations or electronic goods by an error committed by the electrician.

Electricians should also consider getting general business insurance, as well as workers’ compensation and disability insurance. This can help protect them against any unforeseen events that may occur on the job, such as property damage or injury to themselves or others. In addition to these types of insurance, it is also a good idea for electricians to have professional liability insurance. This will provide protection in the event of a dispute with a client over payment or quality of work.

Insurance

Having insurance is an important part of running any business. There are a variety of policies available, and the type you need depends on your particular business needs. It’s also a requirement in some locations to carry certain types of coverage in order to be able to bid on contracts.

The insurance requirements for an electrician can vary from state to state. In general, a professional electrician should have general liability, commercial property, tools and equipment, and workers’ compensation coverage in place. The cost of these policies can vary depending on the number of employees, the type and amount of coverage purchased, and other factors. Often, bundling these policies with workers’ comp or commercial auto insurance can result in savings.

Liability insurance is generally a requirement for electrical contractors to be licensed in certain states. It is a way for the public to know that the contractor has financial resources available to cover damages caused by work performed. In addition, carrying a specified amount of liability insurance is sometimes a requirement when bidding on government construction projects to minimize the financial risks for the project sponsor.

In addition to general liability, an electrician should have professional insurance (Errors & Omissions or E&O) in place. This type of policy protects the company against claims made by clients that they have not been satisfied with the quality of the work performed. It may also help pay for legal fees if the business is sued over unsatisfactory work.

Fred worked as a construction electrician for over ten years, so when he received a windfall from an inheritance, he decided to start his own business. He began by purchasing a standard BOP and didn’t give much thought to risk management. As his business grew, he needed performance bonds and found an independent agent who was knowledgeable on the subject. He helped Fred get the right amount of coverage and explained other specialized products that are also available, such as surety bonds. This helped Fred secure the contract he needed to keep his growing business going strong.

Safety

While working with electricity may seem relatively safe if done correctly, it can also be dangerous. Electricians often work in large spaces or in cramped conditions with live electrical wires, which can lead to accidents and injuries if not taken seriously. These electricians must follow strict safety rules and procedures to prevent electrocution or fires.

One of the most important safety requirements for an electrician is personal protective equipment (PPE). This includes items such as hard hats, eye and hearing protection, rubber gloves and mats to protect against falling objects. It is crucial that these items are inspected regularly to ensure they are in good condition.

Another essential safety requirement for an electrician is knowledge of the hierarchy of controls. This outlines the proper course of action when dealing with occupational hazards, starting with eliminating the hazard and moving down the list to engineering control, administrative control and finally, PPE. For example, an electrician should always try to avoid using a ladder that has metal side rails when working near power lines or electricity, as this creates a fire hazard.

Other safety requirements for an electrician include ensuring all exposed electrical parts are de-energized before beginning any work. This can be accomplished by following your company’s Lockout/Tagout procedures, or by shutting off the power to the affected area. Additionally, an electrician should never touch anything that is hot or has an exposed current. Doing so can cause burns or involuntary muscle contractions. Additionally, an electrician should not work in areas that are wet or damp as this can increase the risk of injury from electrical shock or arc flash.

In addition, an electrician must never use a screwdriver as a makeshift multimeter as this can lead to damage or injury. Similarly, an electrician should not operate machinery or work around it if they are not trained and qualified to do so. Furthermore, if an electrician feels that they are in danger of becoming shocked by an electrical current, they should immediately call their local utility company. Doing so can save lives and prevent serious injuries.

Various electrical problems may arise, ranging from figuring out why an outlet sparks to finding the most cost-effective wiring method. Electrical engineers must work with various people, including construction teams and the general public. As with any industry, electricians have to be professional and courteous. Read on

Various electrical problems may arise, ranging from figuring out why an outlet sparks to finding the most cost-effective wiring method. Electrical engineers must work with various people, including construction teams and the general public. As with any industry, electricians have to be professional and courteous. Read on