Residential>Troubleshooting & Repair ServicesGFCI OutletsAFCI BreakersWhole House Surge ProtectionElectrical Safety InspectionsSmoke & CO DetectorsGenerator InstallationElectrical Panel UpgradesDedicated CircuitsIndoor LightingLandscape LightingFan InstallationPool & Hot Tub WiringEV Charger InstallationWhole House RewiringHome Theater InstallationCommercial>Troubleshooting & Repair ServicesDedicated Computer CircuitsElectrical Safety InspectionsSurge ProtectionGenerator InstallationElectrical Panel UpgradesBucket Truck ServicesEquipment HookupsIndoor & Outdoor LightingReviewsService Areas>Montgomery County, PABucks County, PAChester County, PADelaware County, PABerks County, PAPhiladelphia County, PAPhotosTeamBlogDealsCommunityAchievementsComicsCareersCompanies

Bollard Lights For Exterior Landscape Lighting

KB Electric LLC just finished an awesome job for a commercial property involving bollard lights. So today we are going to blog all about bollard lights, their usefulness, and who to call for installation.

What Are Bollard Lights?

A bollard light fixture is a type of fixture that is used for exterior landscape lighting that is ground-mounted. As pictured below, the light fixture is on a bollard, which is a short vertical post. Bollard lighting comes in various types and styles for individual preference. You’ll most likely see a bollard light on commercial properties along pathways and at the front of building entrances. These fixtures can also be used for residential landscape lighting as well.

As with many other types of residential and commercial light fixtures, bollard lighting can either have LED, halogen, incandescent, metal halide, or fluorescent bulbs; however, the majority you will find now are of the LED type. LEDs are more energy efficient than their counterparts, and we recommend going with this option for efficiency, longevity of the bulb, and savings.

Bollard Light Installation

Uses Of Bollard Lights

Bollard light fixtures can be used to:

Illuminate PathwaysHighlight Trees, Gardens, and ShrubberyIlluminate DrivewaysIlluminate Parking LotsIlluminate Building Entrances

bollard lights

Types Of Bollard Lights

Line Voltage

This type of bollard lighting uses line voltage, or 120v, similar to your standard home outlets.

Low Voltage

This type of bollard light uses low voltage and a transformer to step the voltage down from 120v to 12/24v.

Solar

Using the power of the sun, solar bollard lights are powered by sunlight.

Styles of Bollard Light Fixtures

There are many different styles and shapes of bollard light fixtures. The main designs you will find online on Home Depot’s website have a rounded dome top, square top, or a circular flat top. A wide variety to match any type of property, these exterior lighting fixtures come in many finishes such as stainless steel, bronze, amber, black, aluminum etc.

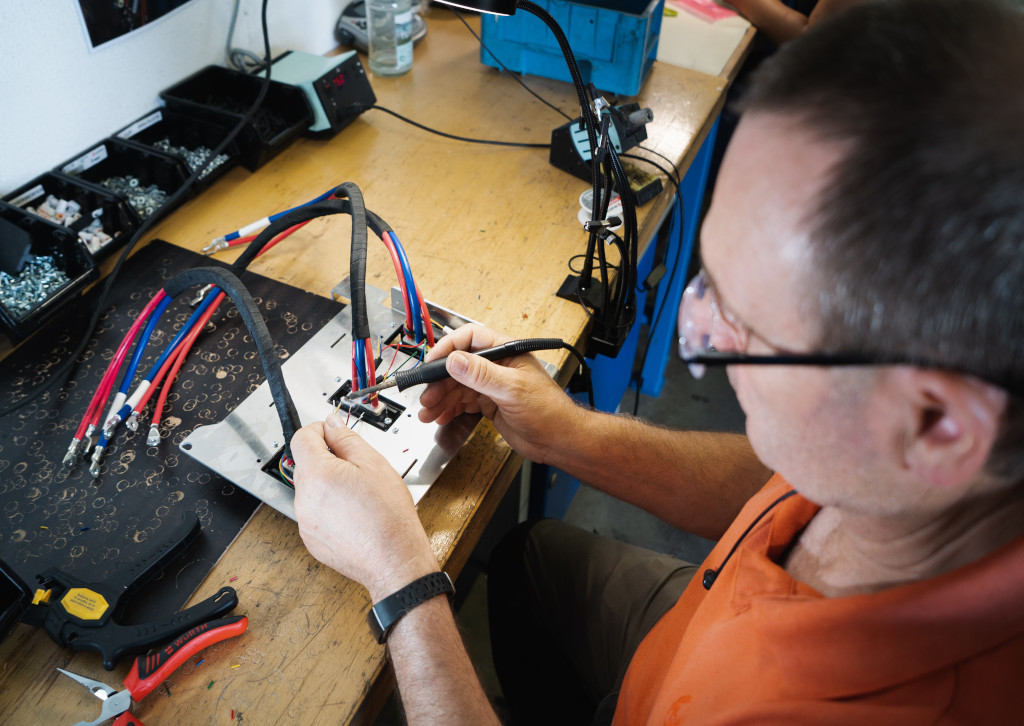

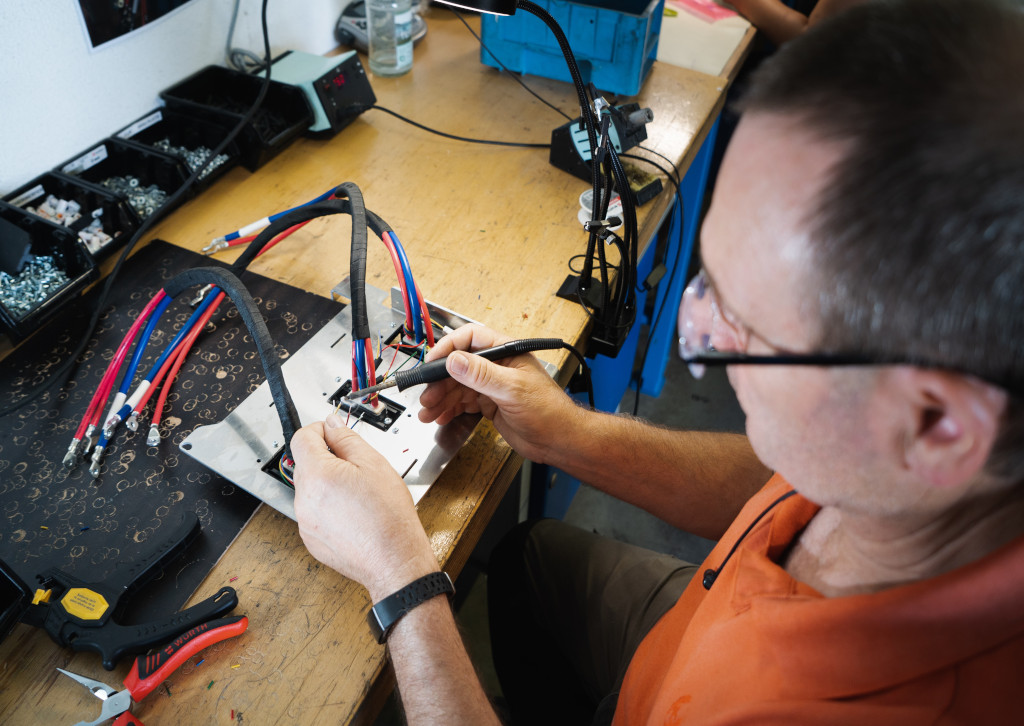

Hire A Licensed Electrician For Bollard Light Installation

The master electricians at KB Electric LLC can install any and all types of bollard light fixtures for your commercial or residential property. We can recommend the best type, and the specific amount of bollard lights needed for any exterior landscape area. Our licensed and insured electricians have the field experience and NEC (National Electrical Code) knowledge to install them safely and properly. Call us today for all of your bollard light installation needs! (267) 467-3178

CATEGORIES

4-Prong OutletsAbout KB Electric LLCAttic FansBallast ReplacementBathroom LightingBollard LightsCable Outlet InstallationCarbon Monoxide DetectorsCeiling Fan InstallationChandelier InstallationChristmas Light SafetyCircuit BreakersCommercial Electrical Safety InspectionsCommercial ElectricianCommercial LightingCurrent Events with ElectricityCurrent Events: EnergyDeck LightingDeck Receptacles/OutletsDedicated CircuitsDeicing CablesDimmer SwitchesDisposing Light BulbsDoorbellsDryer Booster FansElectricity and Energy InnovationsElectric Baseboard Heater InstallationElectric Car Charging InstallationElectric Radiant Floor HeatingElectrical InformationElectrical InnovationsElectrical Panel UpgradeElectrical Remodeling ServicesElectrical Safety InspectionsElectrician vs. Electrical InspectorElectricity BillElectromagnetic FieldsEmergency DisconnectsEmergency Lighting and Exit Sign LightingEnergy Saving TipsEthernet Wall JacksEV Charging SafetyExhaust FansFestoon LightingGarage WiringGeneratorsGFCIsHigh Bay LightingHire a Licensed ElectricianHistory of Ceiling FansHistory of the Dimmer SwitchHistory of Electric CarsHome Electric Car Charging InstallationHot Tub WiringHouse RewireIn The NewsIntercom SystemsKitchen LightingKnob & Tube WiringLED Ballast BypassLED Christmas LightsLED Retrofit LightingLEDsLi-Fi TechnologyLight Color TemperatureLightingLightning FactsLow Voltage Landscape LightingMotion SensorsMoonlightingOutlet SafetyOutdoor Ceiling FansOutdoor Home Security Lighting TipsOutdoor Lamp PostsOutdoor LightingOutdoor Outlet CoversOutdoor Receptacles/OutletsOutdoor Shed WiringParking Lot LightingPendant LightingPhotocell SensorsPool WiringPower and Communication PolesProperty Management ElectricianRange HoodsRecessed LightsRecessed OutletsRenewable EnergyRomex WiringRV Home Electrical HookupSafety & PreventionShed WiringSingle Phase to Three PhaseSmall BusinessesSmart Light SwitchesSmart OutletsSmart ThermostatsSmoke DetectorsSolar Powered ElectricitySpace HeatersStorefront LightingSurge ProtectionSwimming Pool Electrical SafetySwimming Pool Area LightingSwimming Pool LightingThanksgiving FunTools of the TradeTrack Lighting InstallationTransformersTunable White LEDsTV Wall Mount InstallationTwist Lock ReceptaclesUnder Cabinet LightingUSB OutletsVideo Doorbells

The post Bollard Lights For Exterior Landscape Lighting appeared first on KB Electric LLC.

Did you miss our previous article…

https://countryelectric.biz/?p=204