Electricals are a crucial part of any new house in residential construction. It would be best if you did your research before choosing an electrician.

Ensure that the electricians you choose are fully qualified and insured. It would be best if you also were realistic about the projects that they can take on. Visit https://www.epicelectrical.com/ to learn more.

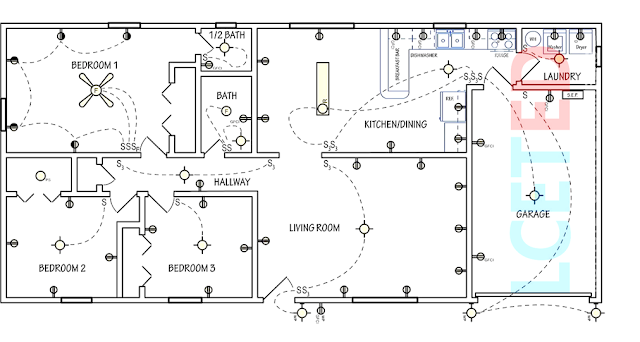

A new home requires electrical wiring for lighting and power distribution, permanent and portable appliances, telephone, heating or ventilation control, and entertainment systems. Contractors carefully design the system, considering safety measures and efficient power distribution. They also work with inspectors throughout construction to acquire permits and ensure compliance with codes and regulations.

The first phase of residential electrical construction involves running wires from the electric box to light fixtures, receptacles, and switches. This process usually takes a few days for smaller homes and between a few weeks and months for larger homes. This stage of construction also includes the installation of exhaust fans and special lights, as well as the wiring for any security or entertainment systems.

There are several different types of electrical wiring, depending on the needs of the building. For example, single-family homes use a three-conductor twisted pair of “triplex” cable that contains a bare ground wire, a stranded neutral wire, and two insulated line conductors. Its outer sheath is often plastic (Romex) or metal (NM). Some areas require conduit, while others allow for bare wires. Some communities have ordinances that limit the type of house electrical wire that can be used.

Wires have markings that indicate their size, material, and other information. When buying new wire or cables, it is important to read the labels to ensure that you have the correct materials for the job. The markings are usually printed or stamped on the insulation and sheath.

In commercial settings, there are higher power demands and more specialized insulative requirements. Commercial wiring typically has thicker insulative coatings than residential wire and is often run in conduit. This can make it difficult to install and repair, but many products are designed to help make the job easier. Some of these include pre-insulated wiring kits, conduit connectors, and crimping tools that help to connect or remove wires without damaging the insulation. In addition to these accessories, there are several ways that contractors can protect the integrity of the wires when installing or replacing them.

There are many types of electrical outlets. While they may look similar at a glance, each has its purpose and offers a variety of perks for homeowners. Depending on where an outlet is placed, it can add extra functionality and even safety features to a home.

Standard outlets are the ones we see in most homes, fitting a two- or three-prong plug and supplying 120 volts of electricity. These are versatile enough to power most home appliances but also meet the standards of places like hotels or public areas where people constantly plug in and out of devices.

Another type of outlet commonly seen is the GFCI (Ground Fault Circuit Interrupter) outlet. These are typically found in bathrooms, kitchens, laundry rooms, and basements as they help protect against electrical shock from water leaking into or touching an outlet. They have a special slot for a grounding rod that works to prevent electrical shock from excess current running through the wiring.

A tamper-resistant outlet has an internal shutter that only opens when a proper plug is inserted. This can help prevent curious children from inserting foreign objects into an outlet, which could cause a serious injury. It’s a good idea to install these in your new home, especially if you have young children.

Many homes have a mixture of these traditional outlets as well as more modern ones, such as USB ports or Smart outlets. Smart outlets can offer several added perks for homeowners, such as controlling lighting, heating, and other home systems with the touch of a button. They also allow you to plug in phones and tablets without a bulky extension cord.

Residential electricians will install the required number of outlets according to local electrical codes. However, you can always ask them to put in more where you think you’ll need them, such as above the garage door for a garage door opener or inside your built-in cabinets for TVs and entertainment systems.

Switches are used to control lighting and other devices, such as receptacles. They come in several styles, including toggle, rocker, and push button switches, but their style doesn’t affect the switching mechanism or wiring. The type of switch you use is usually determined by the device that you’re trying to control.

Whenever an electric current passes through a switch, it creates sparks when the contact opening is closed or opened. The sparks occur because the electric field created by the current breaks down and ionizes the air particles, causing the electrons in them to jump across the gap between contacts. The more ionized the air is, the bigger the sparks will be when the switch opens or closes.

These sparks are necessary for the electrical circuit to operate properly, but if they become too large, they could cause fire hazards or damage the circuit’s equipment. Over time, a switch that is continually being switched on and off can develop deformations in its contactors so that the contactors no longer separate the way they are supposed to. This will eventually reduce the switch’s lifespan and cause it to fail sooner than its rated parameters indicate.

For safety, it’s recommended to always use the proper rating for any switch that you’re installing in your home. A single-pole switch is typically a workhorse that you’ll find in many homes. It has two brass-colored screw terminals that allow you to control the flow of electricity through the incoming and outgoing “hot” wires (usually black) in the switch’s circuit. It also has a green screw connected to the circuit’s grounding wire.

Three-way switches are used in pairs and are often found at the ends of staircases or in garages that have two entries. These switches feature three screw terminals, with the darkest one being labeled COM for common and the other two screw terminals being labeled travelers. The traveler wires connect to both the common and the light fixture that you want to be controlled by the switch. Either of the two three-way switches will then prevent them.

A residential electrical system is a complex network of wiring, outlets, and switches. Electrical engineers are trained to assess electrical requirements and determine the best solution for each home. Their meticulous attention to detail ensures that your electrical systems meet all requirements and run efficiently throughout the property.

The electrical system in a building begins with a step-down transformer provided by the utility company. The transformer reduces the standard line potential to two dual voltage systems distributed through master switches and electric meters. Then, the distribution system splits into individual circuits for lighting, appliances, and ceiling-mounted non-incandescent lights. Each of the circuits contains a fuse or circuit breaker that helps direct sudden demands for electricity and prevents overflow that can cause fires.

Grounding is another critical component of any electrical system. This method connects the electrical system to the earth with a wire and provides a third path for electricity should any of the circuits in the house experience an overload or short circuit. This grounding system also protects people from electric shock and electrocution.

One of the most important tasks for an electrician is determining how much power each load will require and establishing branch circuits to power them. This involves evaluating conduit and conductor sizes to determine the best fit. For example, three AWG #12 wires require a larger conduit and cable size than four AWG#6 wires. It’s also important to determine the proper length of wire and the number of fuses or breakers required for each load.

Finally, electrical engineers must work closely with planners to determine schedules for construction activities related to the electrical elements of a building. They also need to be flexible and adaptable as project requirements change.

The bottom line is that without an experienced and knowledgeable electrical engineer on your team, your project will likely experience delays and cost overruns due to misdiagnosed issues or unanticipated problems. A skilled and professional electrical contractor will work with you from the beginning to avoid these pitfalls. They will be able to help you create a cost-effective plan for your electrical needs, whether that’s a complete remodel or new construction.